By using micro-optical elements complex systems can be miniaturized. Therefore we developed a multichannel microspectrometer which enables hyperspectral imaging despite a miniaturized design. The high-performance system covers various applications in the field of precision agricultur, life science or food industry.

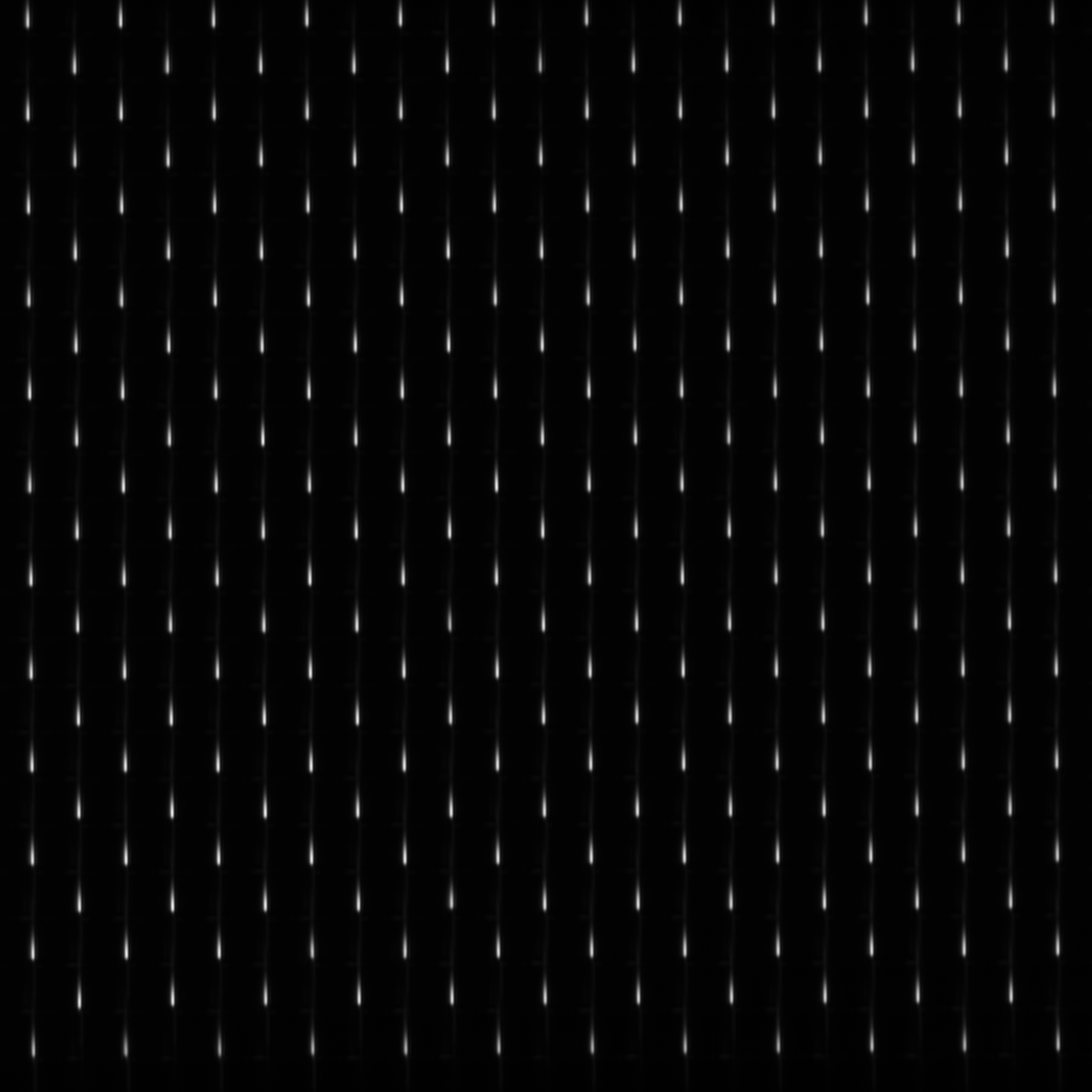

Single Channel View

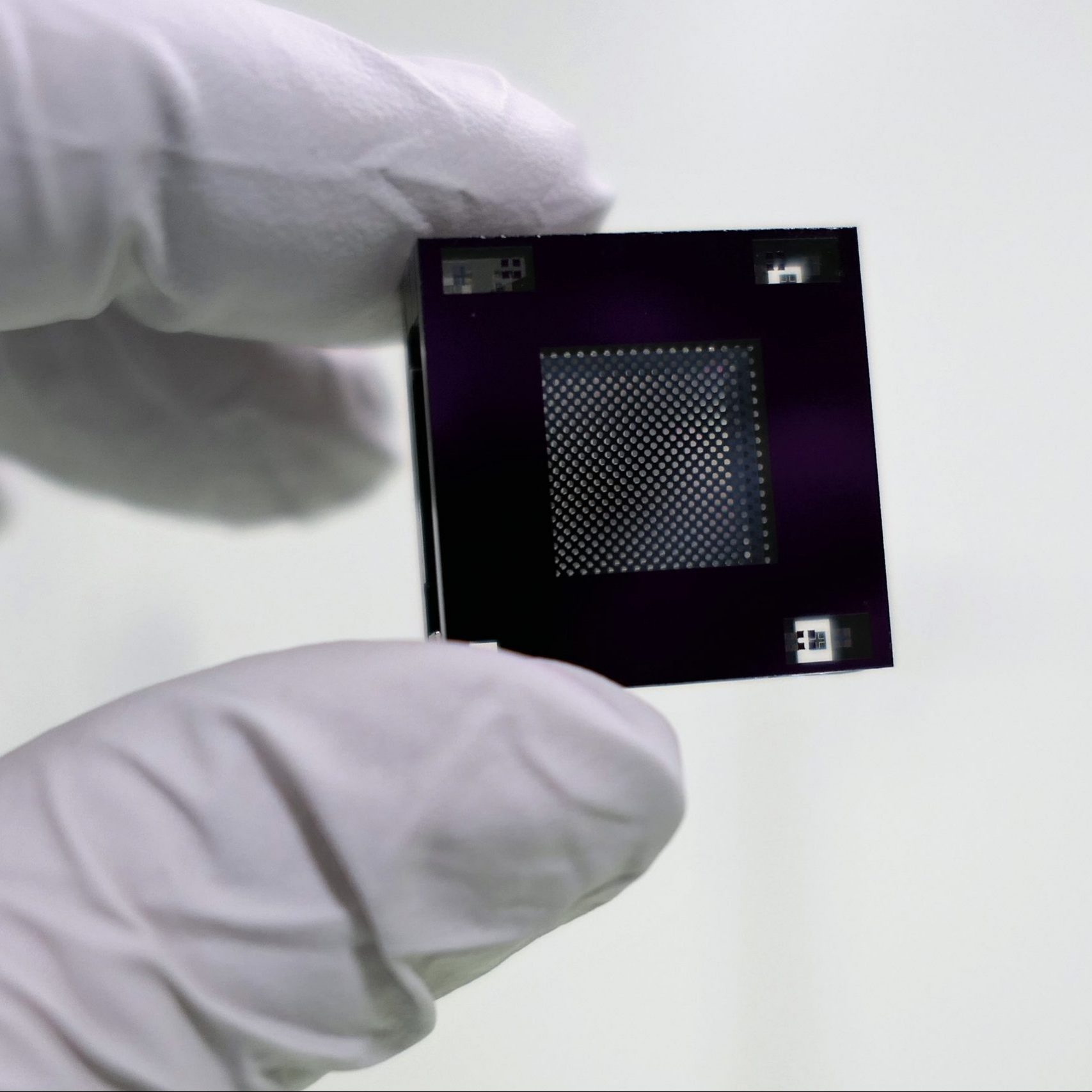

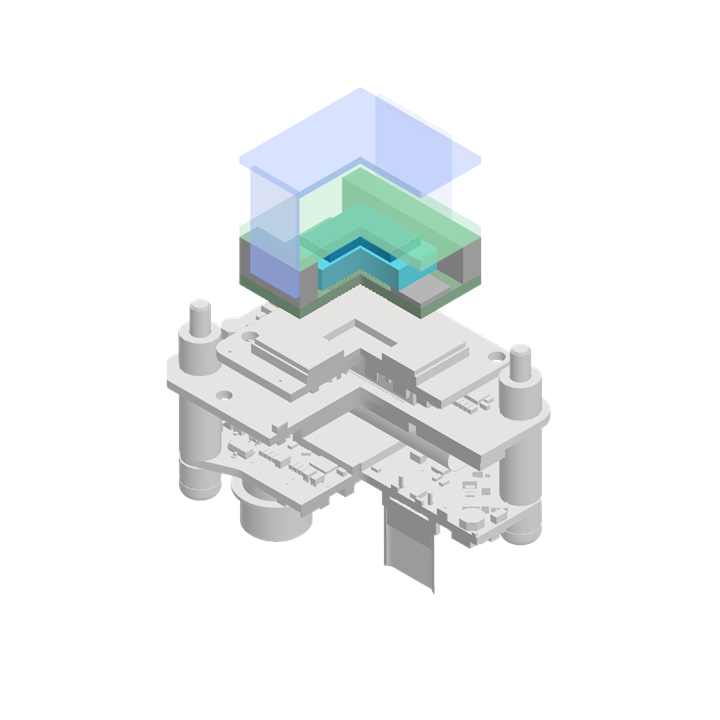

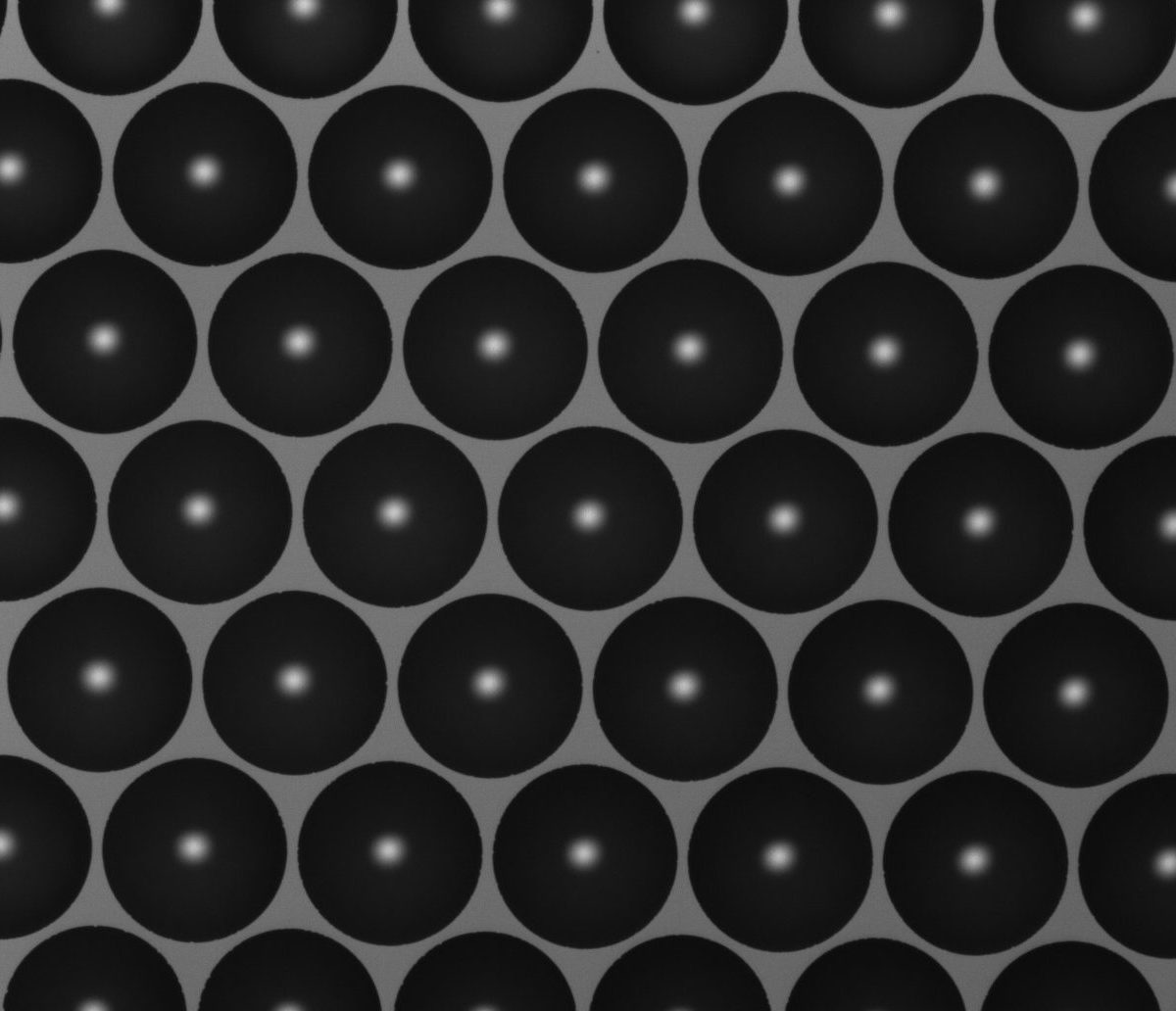

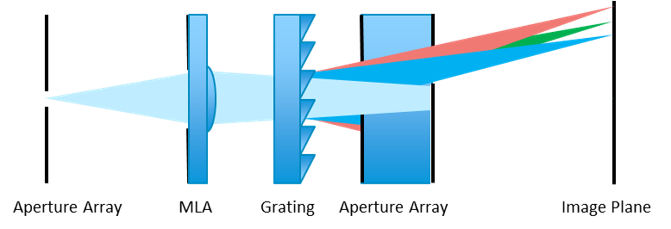

The microlens array images object points to the image plane, while the blaze grating splits the light spectrum in the single wavelengths. Afterwards, the integration of various aperture arrays serves to separate channels and eliminate stray light. In the microspectrometer 256 individual channels are arranged in a periodic pattern – within the size of just 2,5 cm. The sensitivity stretches across the whole spectrum of visible light so commonly used RGB camera sensors can be utilized for image data processing.

Technology

Mask Design

- preparation of mask data for all elements produced by lithography with special attention to alignment structures on each layer (front and back side of the substrate)

Lithography

- coating

- spincoating of resist

- UV exposure

- development

- etching

Nanoimprint Replication

- PDMS stamp fabrication

- replication on OrmoComp® coated glass substrate

Live-Video Assembly

- multi-dimensional movement of pinhole array (x, y, tilt, turn)

- precise adjustment (micrometer range) of all optical components with alignment structures

At a glance

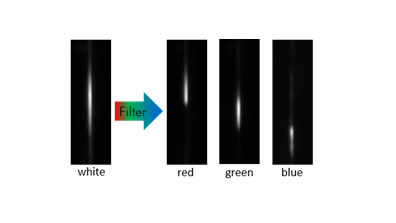

The whole technology chain – from optical design to production of all components with state-of-the-art technologies like nanoimprint lithography – was completely realized by POG. The performance of the microspectrometer, especially the homogenous illumination of all the single channels, was verified during multiple testing procedures with different color filters and illumination scenarios.

Would you like more information about your individual options?