Laura

Trainee Precision optician

Trainee Precision optician

Development engineer

Microtechnologist

Precision optician

Microstructuring specialist

Deputy Head of Department

Lithography/Coating

Laura

Trainee precision optics

Your training at POG – how did that come about?

I actually had completely different plans. Since I was passionate about sports, I wanted to train as a fitness instructor. And that’s what I did. But I quickly realized that it would not be my ultimate career. Still, I completed training and graduated. My sisters were already at POG at that time, and I was intrigued by their stories. So I took a closer look.

Starting all over again after three years of training?

Well, the decision wasn’t quite that easy for me. Actually, I wanted to work and earn money after my training and not continue with further schooling.

What finally convinced you?

A trial internship at POG. I really felt at home here. I liked the work, the team and the trainer were super nice. Also, I had a lot of respect for the subject matter. After all, the last time I took science subjects was in 10th grade. My little sister helped me!

And what was the start like?

It went straight into practice: I learned what types and shapes of glass there are and what individual work steps are necessary to prepare the corresponding parts for the subsequent work processes. Grinding, polishing, cementing, painting … but not only that. I like to write, and I am now in charge of the project “Buschfunk”. This is a fun and informative newsletter for the POG employees which is produced by the trainees on their own initiative. I’m responsible for planning and implementation, thinking up topics, talking to colleagues about their projects.

How do you want to continue? What are your plans for the future?

Getting a proper degree – that’s my top priority for now. It won’t be easy, but my team, my instructors and my classmates are by my side. That feels good!

“Highly interesting in terms of content, very varied and creative” – this is how Tobias calmly but with a certain fascination describes his job at POG. “The interplay of optics and microtechnology brings this diversity to the daily work.”

In July 2015, Tobias arrived at POG as a development engineer for optical systems with a Master of Engineering in his pocket. Even before and during his studies, the practical component played an important role for him on his way to professional life. Lasers and optotechnology seemed to be the perfect choice for the math and physics enthusiast. And with the Ernst Abbe University just around the corner, Tobias didn’t want to venture far.

From study directly into practice

As a student, he diligently invested five years of his life in optics, optoelectronics, laser and measurement technology. His focus, that today lies in the technological advancement of microstructures, optical systems and test engineering, was already apparent to him during his studies. And now, five years after his graduation, it is still his passion.

“I was able to acquire a broad range of expertise during this time” – and he can put this to profitable use when designing or constructing test setups or programming software and tools. One example is the construction of a microspectrometer as part of a grant project. The technologies used here are completely new – not only for Tobias, but for POG as well.

Pulling all the strings

Gripped by the challenges, he is intimately a part of the process from planning to demonstration. “I’m involved in all aspects of the process – including optical design, construction, manufacturing and assembly. Starting with the calculations and modeling of the optical elements, accounting for the required performance and ensuring technological feasibility. I continue with the development of the overall design, including the functional and auxiliary elements, integration of lighting and cameras, etc. And ultimately, the development the processes by which micro-optical elements are replicated by imprint processes. For the assembly of the micro-optical elements, POG requires a completely new paradigm. We design test setups and fixtures for integration.”

It sounds complex because it actually is! POG’s portfolio ranges from classic precision components to microstructured optics – much of it entirely customized. Individuality, optical design and innovation are fundamental building blocks that Tobias utilizes – and with which POG and our customers can construct the future with confidence.

Tobias

Development engineer

Aileen

Microtechnologist

“When my father discovered the POG exhibition stand at the training fair in Gera in 2015, I could not yet imagine the exciting and varied projects in which I would one day be involved. At that time, like many of my classmates, I was not at all sure what my profession would be. But I could rule out so many things.”

During the conversation at the POG exhibition booth, I got a first, rough impression that made me curious. My favorite subjects, biology and chemistry, could find partial application. To get a better insight, I did an internship at POG during the following fall vacations. One week, I could get a taste of being a precision optician; while another week, that of a microtechnologist. I ended up pursuing the latter. Why? Just a gut feeling at the time. But it was immediately confirmed during the first few weeks.

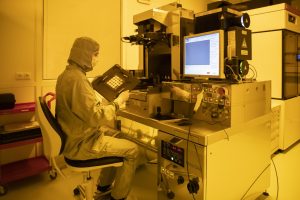

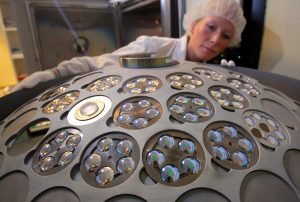

The work in the clean room was very exciting right from the start – for example, the photolithographic process of our standard microstructures. Here, an exposure process is used to transfer structural information from a so-called photomask to a light-sensitive photoresist, and then the exposed areas of the photoresist are dissolved. This creates a lithographic mask, which is further processed using chemical and physical processes.

Of course, I couldn’t start my training with these complex topics right away. At the beginning, grasping the basics were the priority. I had to learn how to plan, organize and document work processes. To carry out the individual work processes, I then received precise instructions on how to operate and monitor the necessary equipment. Not only is the handling of working materials very important, but also the storage of materials and chemicals, while always taking into account safety and occupational health regulations.

For me, there was no doubt that after a 3-year training period, I had found my profession. Here at POG, hardly any day is like the other. Customer-specific microstructures, or the application of various microlithography processes, are always presenting new challenges.

The variety of tasks not only helps me to constantly expand my knowledge and consolidate what I have learned, together with the help of my experienced and very nice colleagues, but they also ensure that everything is more than just simple routine.

“When technologists ask me for advice on whether I can implement their ideas on our machines, I look back on my career with pride. I actually wanted to become a precision sheet metal worker because my buddy did the same. But at the time, there were no apprenticeships available.”

After starting his training as a precision optician in 1977, Ralf joined ZEISS in Gera in 1981. By the time the company was wound down operations in the early 1990s, he had gained a great deal of professional experience in the field of spherical optics, which meant that a position as a master optician was firmly in his future. Motivated by this assurance, Ralf began to study on the side for the master’s certificate. But then came Reunification, and with it uncertainty and worries about the future – especially after takeover negotiations failed.

Turbulent times – new perspectives

“Unfortunately, I had to end my master’s degree, but thanks to the courage and ambition of the company’s founders at the time, there was a chance for me and some of my colleagues to preserve and further develop the tradition of optics manufacturing at the Gera site – as POG.” Completely new to the market, but not inexperienced, POG needed new machines to execute customer orders.

The optics production line for single lenses was purchased, and Ralf was instrumental in getting it up and running. “I was given responsibility for this manufacturing area. It challenged me enormously and I still enjoy adjusting the CNC technology to the grinding and polishing processes down to µm accuracies.”

Heart and soul of the next generation

But Ralf does not only apply his great care to his own work. Equally important to him is the training of junior staff in the company, in which he is actively involved through the sharing of his professional and life experiences. “POG quickly realized that the growing need for qualified specialists is best met from within its own ranks. Since 1995, we have therefore been training young graduates to become skilled workers.”

Proud of the courage and ambition

Ralf looks back on those eventful and instructive years, and is glad that he dared to follow his heart during an uncertain time. His wish for the company, his colleagues and the next generation, is that this passion, coupled with courage, confidence and ambition, will always remain – so that POG may successfully continue what began for him 30 years ago in Gera.

Ralf

Precision optician

Tina

Microstructuring specialist

“Math and physics advanced course – but studying? As a person interested in handicrafts, that seemed much too dry for me; it should be an apprenticeship. After I had sent my first applications for an apprenticeship as a physics lab technician, I found out about the job description of a precision optician and POG as a training company via some detours.”

My interest was immediately piqued. And the 4-hour work trial, in which a glass cube was to be produced, immediately convinced me and (fortunately) also POG! Because from 1.9.2006 I could begin my training as a precision optician at POG, which at the time was still in the Keplerstraße plant in Gera. I really enjoyed the apprenticeship because craft skills merged with high-tech processes. The opportunities that arose during the 3.5-year training period made me very excited, and also a little impatient about the future.

Ready for university as valedictorian

I graduated at the top of my class in Thuringia. I was now ready for even more learning in theoretical sciences. With POG backing me up, I didn’t have to worry. My return to work was assured and I could also earn money during the semester breaks. So in 2010 I started my 3-year degree program in Lasers and Optotechnology at the Ernst Abbe University in Jena. And in 2013 I had my Bachelor of Engineering in hand. Additional courses such as microsystems technology made the studies very exciting, and not at all as far removed from practice as I thought while studying. It was clear to me that microtechnology would continue to play an important role in my professional career.

When I’m asked today what my job is at POG, I can briefly say – manufacturing engineer for structured optics. What does that entail? – A variety of exciting, sometimes routine, but always challenging tasks from customer support and preparation of quotations to the preparation of manufacturing documents, drawings and test documents. A large part of my work involves supporting and developing manufacturing technologies and machines instrumental in production. Here, I am very close to the practical implementation of individual projects and can therefore guide each customer request individually and actively monitor the development process.

Perfect job – also at the new location

A very exciting time for me and my colleagues was the move of the entire company to Löbichau, where my responsibilities, among other things, consisted of disconnecting the „wet“ equipment in the old clean room and determining the installation locations of the individual machines in the new building. I am proud and grateful to be able to play an important role in supervising machines and production processes. I have a wonderfully supportive employer in POG that encourages my growth; I maintain close relations with customers; my manual skills are always put to practical use; my curiosity is satisfied by my research work; and I can pass on my knowledge to the younger employees. I would happliy take this path again at any time.

A very exciting time for me and my colleagues was the move of the entire company to Löbichau, where my responsibilities, among other things, consisted of disconnecting the „wet“ equipment in the old clean room and determining the installation locations of the individual machines in the new building. I am proud and grateful to be able to play an important role in supervising machines and production processes. I have a wonderfully supportive employer in POG that encourages my growth; I maintain close relations with customers; my manual skills are always put to practical use; my curiosity is satisfied by my research work; and I can pass on my knowledge to the younger employees. I would happliy take this path again at any time.

Your path began quite classically with an apprenticeship at POG. How did you become aware of the profession and the company back then?

As a schoolgirl, I have to be honest, I knew nothing of the profession of precision optician. During a school trip to the career information center, we were given some tests to show our professional strengths and weaknesses. There, we learned which professions might be suitable for each individual. My strengths have always been in the natural sciences, and that’s the direction I wanted to go. The more I looked into the job of a precision optician, the more curious I became. I also learned from the career information that POG was a reputable training company. So I didn’t hesitate for long and submitted my application.

What was your first contact with POG like?

After my application, I was invited to a trial day. There was an interview and an assessment test. During this, I had to make a glass cube. But what impressed me most was that the managing director personally accompanied me throughout the day and took the time to give me an understanding of the company and its products. This was ultimately decisive for my decision to start my training as a precision optician at POG in 1998.

What professional experiences did you collect during and after your training?

During my training as a precision optician, I gained comprehensive insights into many areas. I was able to quickly learn the job-related activities with the help of my colleagues and instructors. I was then deployed for a longer stint in the coating department. The skills and abilities I developed in this area were critical for my career following my vocational training. I enjoyed the work very much right from the start. In the beginning, the optical components were still cleaned by hand. Of course, this has changed and developed over the years. Part of the cleaning now takes place in ultrasonic bath systems. Back then, the coating machines were operated completely manually – even during the coating process itself. Today, this is mainly done automatically using ultra-modern coating and sputtering systems. As a result, maintenance and servicing of the equipment are now the most critical and, of course, time-consuming.

You also started a family. What happened after your parental leave?

After my maternity leave, I went straight back to work and became involved in fine cementing. This is the joining of two or more optical components at their functional surfaces located in the optical path by means of optical cement. There are warm cements, UV cements and two-part cements. The cemented components are aligned on centered using specialized devices. And in assembly, I was involved in constructing, adjusting and testing camera systems. That’s only a small part of my experience, but it’s an essential one.

Did you have the desire to develop personally and professionally?

Definitely. I was very impressed with the initial orientation day during training and by the commitment of the managing director. Passing on knowledge and helping other trainees in the same way were the reasons why I completed my trainee certificate. But then I realized that there is much more knowledge that I can acquire. So I decided to combine my technical know-how with business knowledge and enrolled for the certified industrial foreman course in optics – which I successfully completed in 2011.

Susann

Deputy Head of Department Lithography/Coating

What was your subsequent career path at POG like?

An offer to take over as the Deputy Head of Finishing/Lithography came a few years later, after I had also fulfilled my desire to start a family. The insights and practical experiences I gained during the wide range of activities I performed over the years were a great benefit to me in this new role. But with this new job came new responsibilities, of course, especially in the organizational area. Employee scheduling, planning consultations, coordination between the departments and, quite clearly, the communication, assessment and further development of our employees are an essential part of my job. At the beginning of my professional life, I would never have imagined that I would enjoy this challenge so much.

What is your conclusion after more than 20 years at POG?

The path offered by POG was exactly the right one for me! I would do everything the same way again, and I look forward to what lies ahead.