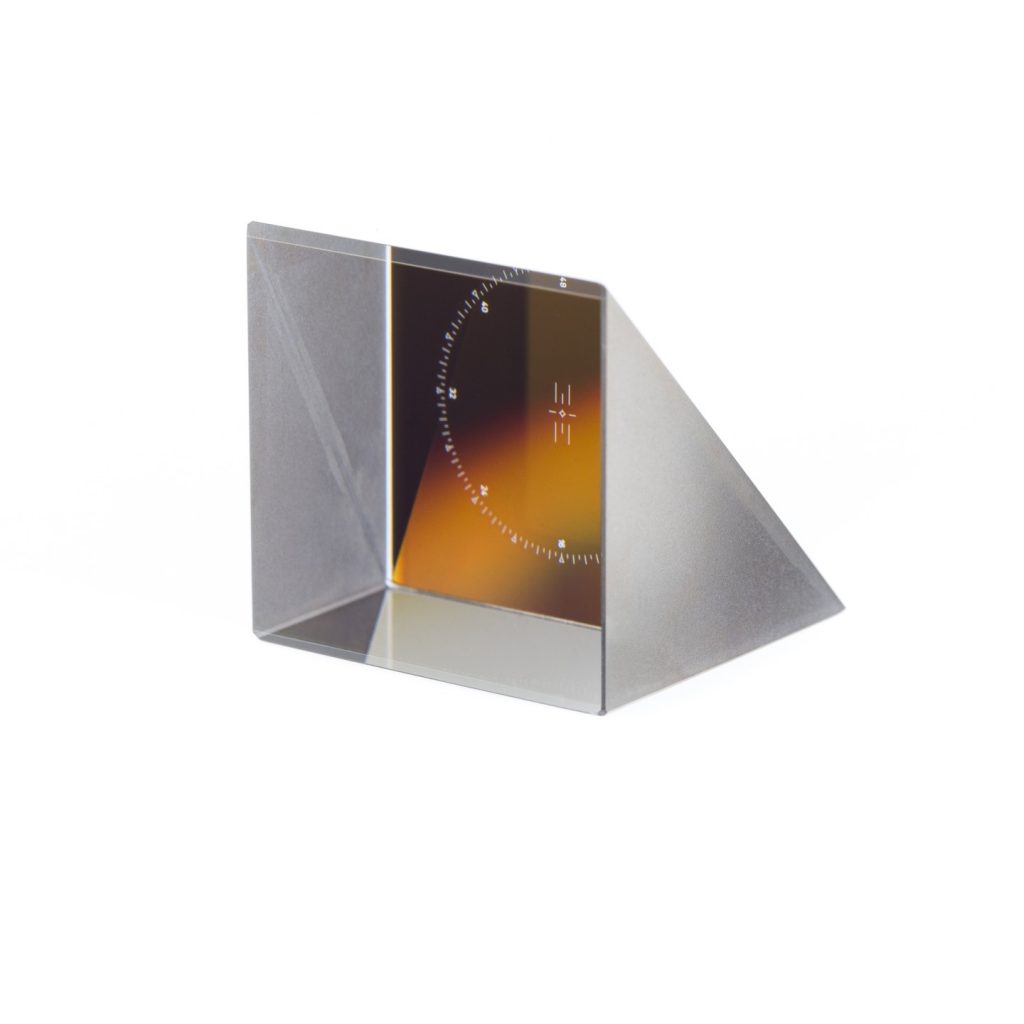

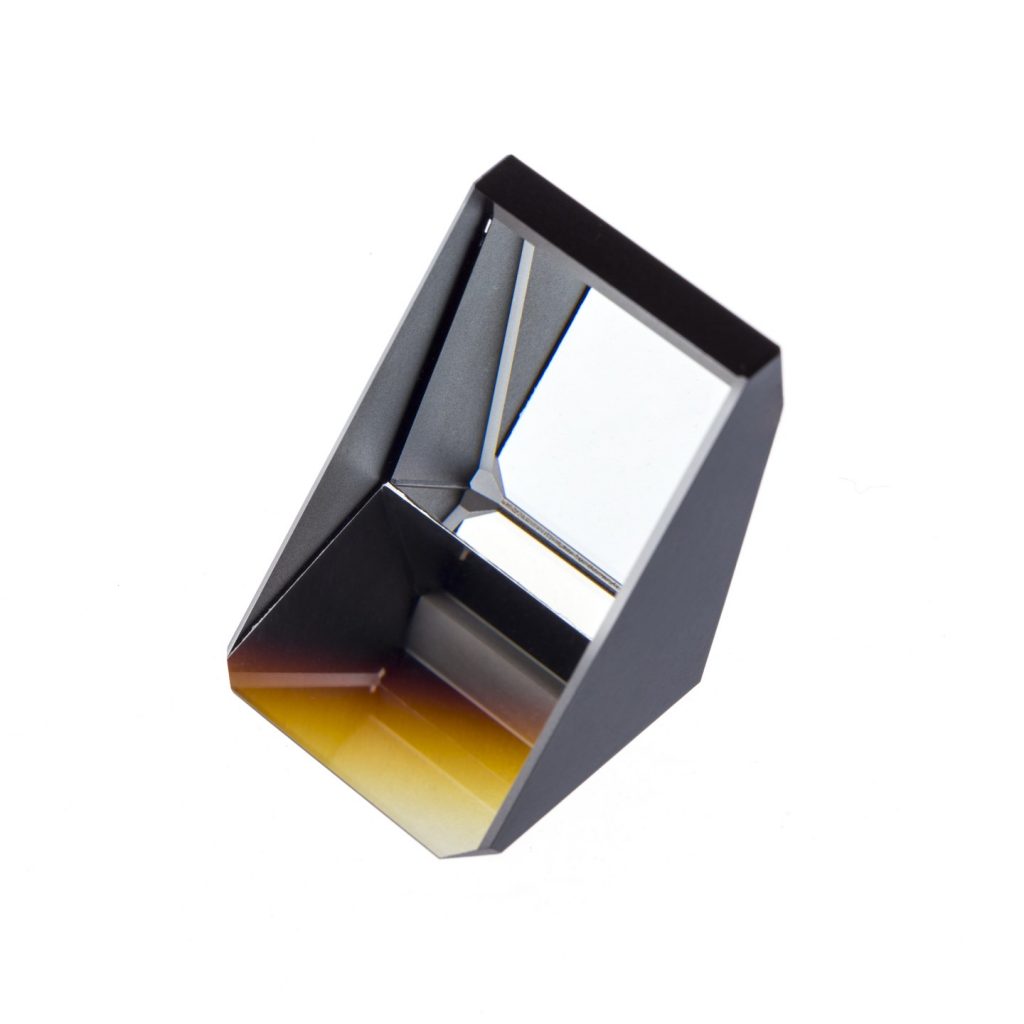

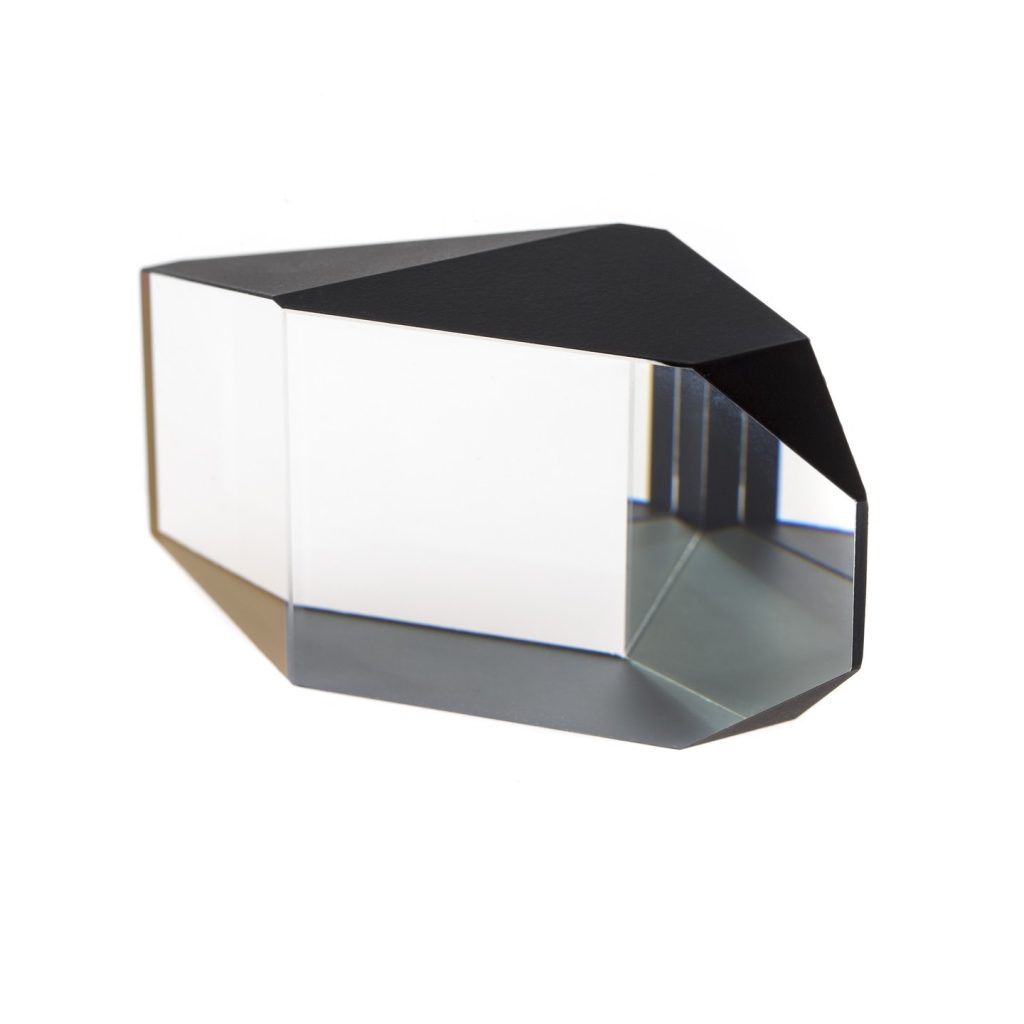

Craft and high-tech for flexible small batch production

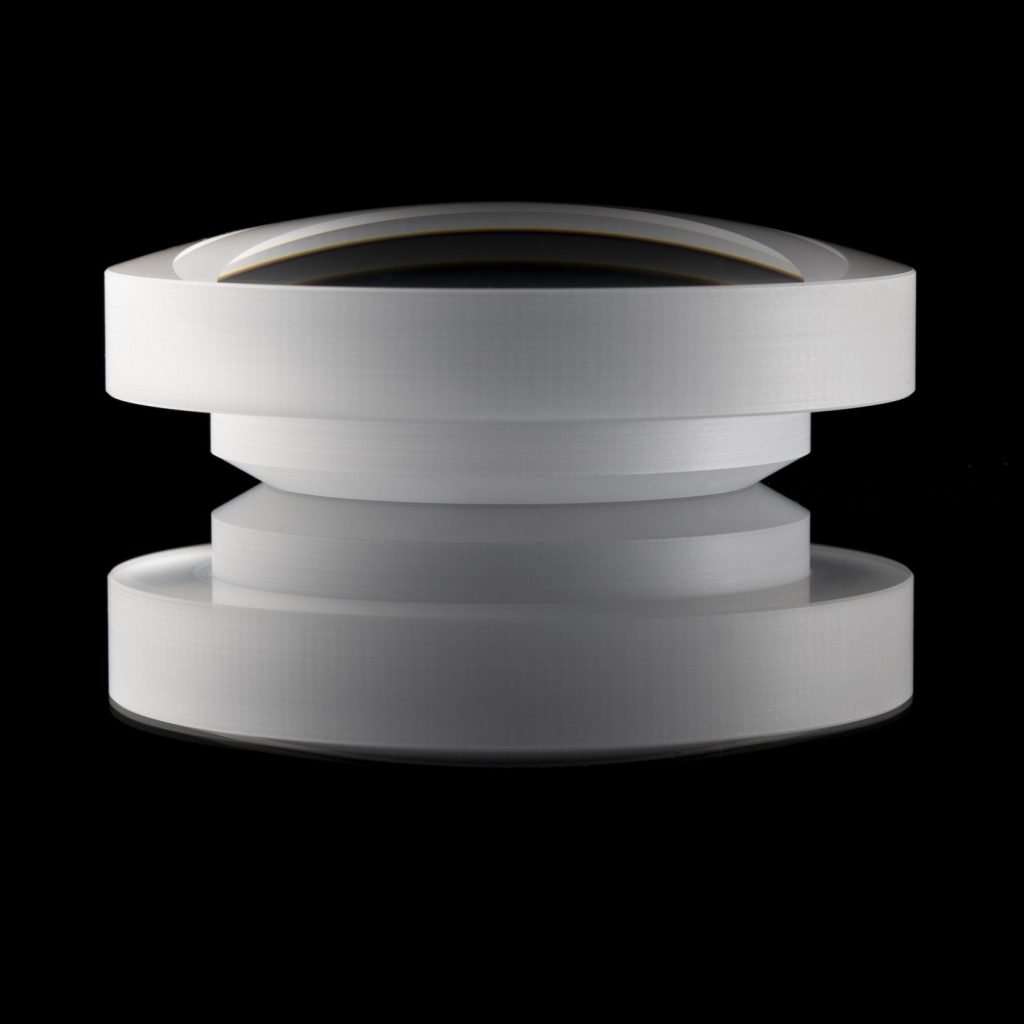

Our optics manufacturing is optimized for flexible production of a wide range of precision optics with challenging demands. Using state-of-the-art equipment, craftsmanship and a lot of know-how, we manufacture your optics for demanding projects in small development quantities – exactly according to your requirements.

Inhouse manufacturing

With an extensive portfolio of manufacturing technologies, we guide the production of optical components entirely in-house. Our highly qualified and experienced technicians master demanding manufacturing processes from prototype to serial production quantities.

This gives us the confidence we will fulfill our promises to you – confidence on which you can rely.

Superior Product Quality

Quality is our foundation – from quotation and product design to final inspection & shipping.

Documented, secure processes throughout all steps ensure the highest product quality.

Options for your custom product

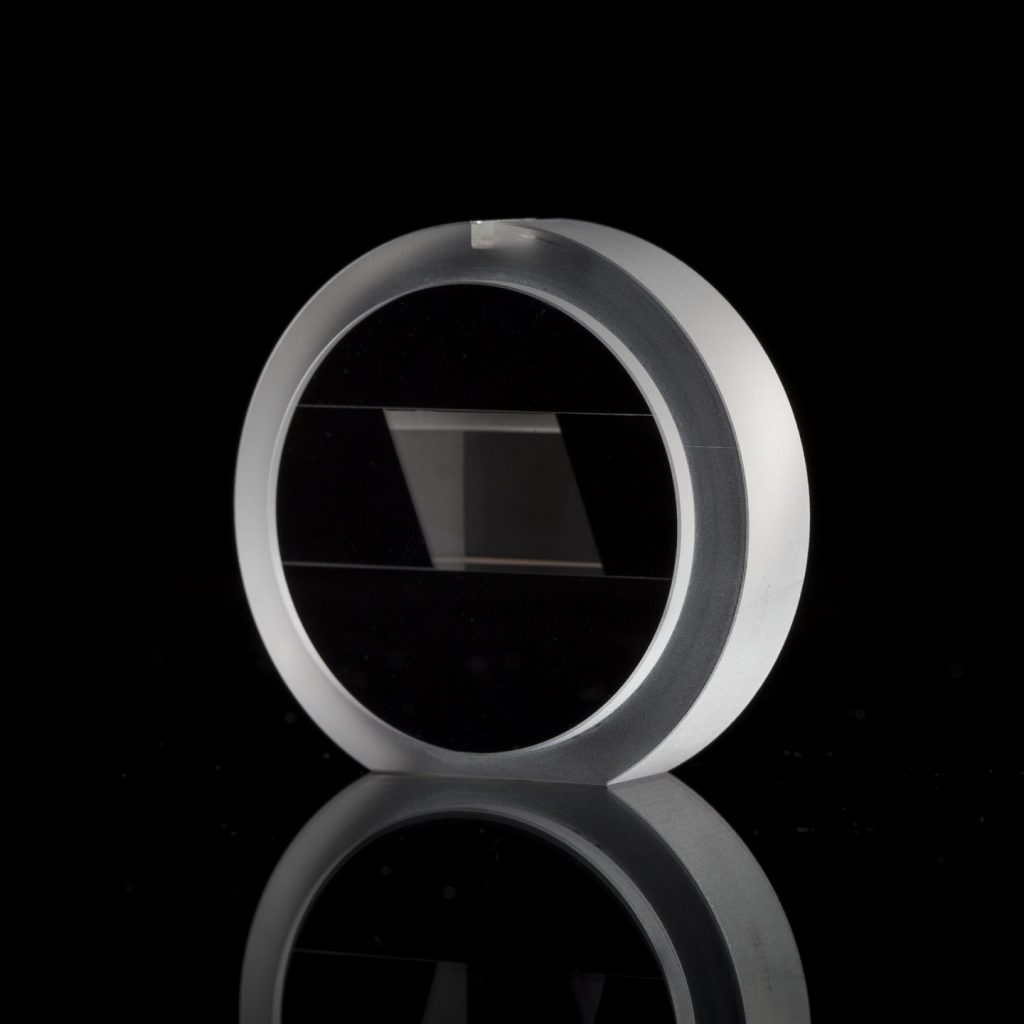

We have extensive experience in processing a wide range of materials:

Optical glasses

all optical glasses

UV materials

Calcium fluoride, quartz glasses for defined wavelength ranges

IR materials

Zinc sulfide, germanium, chalcogenide glasses

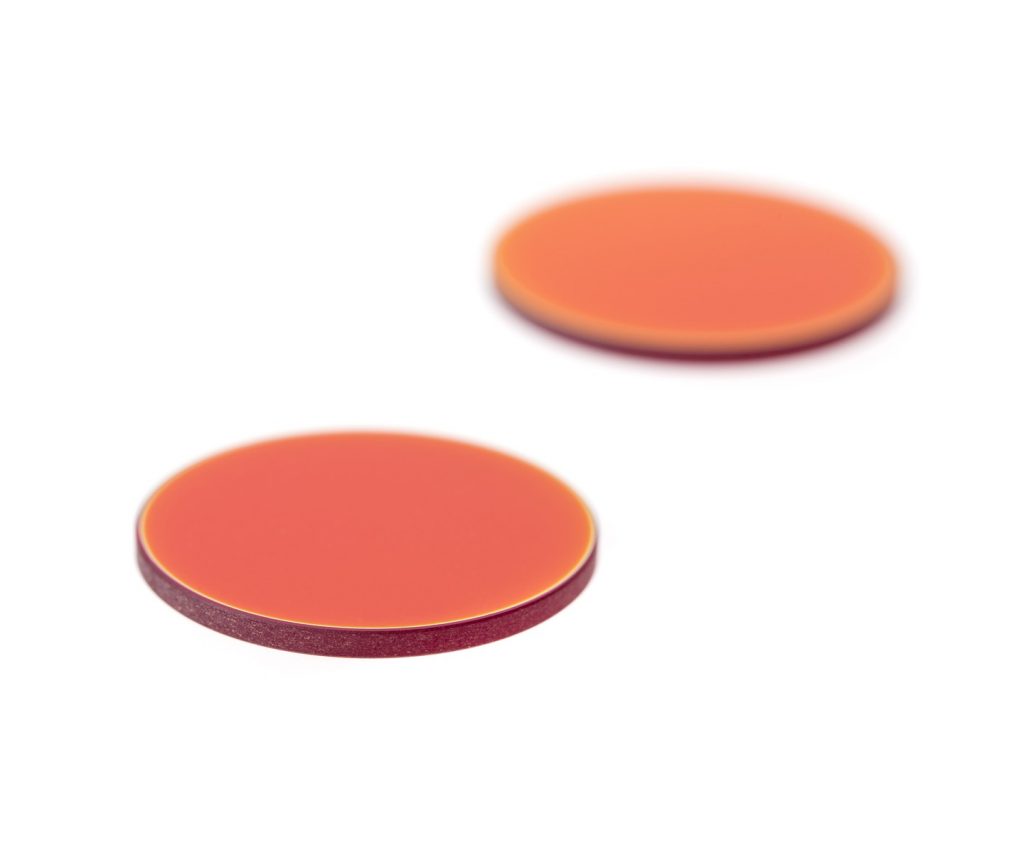

Filter glasses

Band-pass filter, long-pass filter, short-pass filter, neutral filter and others

Zero expansion materials

Zerodur and others

Glass ceramic

Nextrema and others

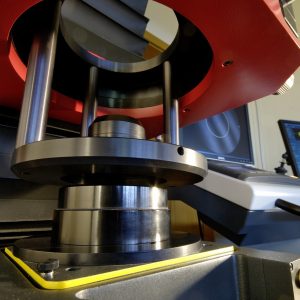

A large number of different measurement and test methods are available in-house for testing the parameters of optical components:

- A variety of different measurement and test methods are available in-house for testing the parameters of optical components:

- Interferometric measurement of surface form deviation

- Roughness measurement with white light interferometry

- Optical and tactile coordinate metrology

- Non-contact and tactile thickness measurement

- Angle measurement with precision goniometers

- Centering test

- Transmission and reflection measurements of DUV-NIR

- Climate resistance test

- Wipe resistance testing

- Defect testing of surfaces according to DIN ISO 10110 and MIL

- Determination of imaging quality by wavefront testing and MTF measurement

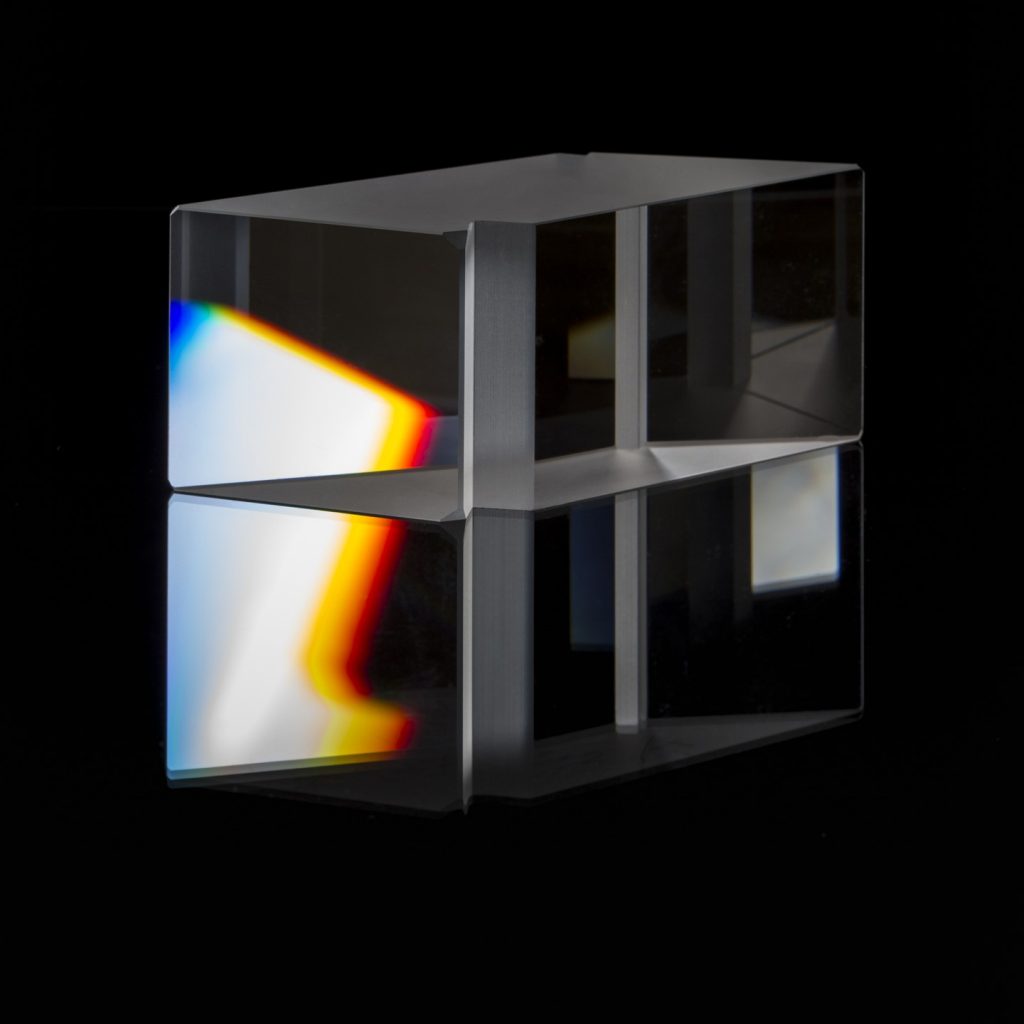

For your project success, we offer a wide range of optical coatings. In addition to a variety of standard coatings, we are also happy to consider the realization of your customized coating requirements.

You can find an overview of the standard coatings here:

Anti-reflective coatings

| Coating Code | Reflection | Data Sheet |

| POG-AR-266 | R(min) @ 266 nm < 0.5 % | POG-AR-266 |

| POG-AR-350-450 | R(abs) < 0.6 % @ 350…450 nm, AOI= 0…15° | POG-AR-350-450 |

| POG-AR-380-910 | R(ave) <= 1.0 % @ 380…910nm | POG-AR-380-910 |

| POG-AR-1064 | R(abs) @ 1064nm < 0,2 %, AOI= 0…15° | POG-AR-1064 |

| POG-AR-550 (MgF2) | R(min) @ 550nm | POG-AR-550 |

| POG-AR-450-700 | R(abs) @ 450-700nm < 1% R(abs) @ 1064nm < 0,5% |

POG-AR-450-700 |

| POG-AR-532_1064 | R(abs) < 0.5 % @ 532 + 1064 nm, AOI= 0…15° | POG-AR-532_1064 |

Mirror coatings

| Coating Code | Reflection | Data Sheet |

| POG-HRA-VIS0 | R(abs)> 90 % @ spec. Wavelength R(ave)> 85 % @ 400…700 nm AOI= 0-15° |

POG-HRA-VIS0 |

| POG-HRA-VIS2 | R(abs)> 90 % @ spec. Wavelength R(ave)> 85 % @ 400…700 nm AOI= 0-45° |

POG-HRA-VIS2 |

| POG-HRA-UV0 | R(abs)> 75 % @ 190 nm R(ave)> 80 % @ 400…700 nm AOI= 0-15° |

POG-HRA-UV0 |

| POG-HRS-NIR | R(abs)> 96 % @ 600…1000 nm R(ave)> 90 % @ 400…1000 nm AOI= 0-45° |

POG-HRS-NIR |

| POG-HRS-VIS0-RV | R(abs)> 96 % @ 550 nm, AOI= 0° R(ave)> 95 % @ 550 nm, AOI= 45° |

POG-HRS-VIS0-RV |

| POG-HRA-VIS0-RV | R(abs)> 86 % @ 550 nm, AOI= 0° R(ave)> 85 % @ 550 nm, AOI= 45° |

POG-HRA-VIS0-RV |

Beam splitter

| Coating Code | Reflection/ Transmission | Data Sheet |

| POG-CBS-50-50 | 50:50 @ 450…650 nm, AOI= 45° | POG-CBS-50-50 |

| POG-BS-50-50 | R= 50 % ± 5 % @ 450…650 nm | POG-BS-50-50 |