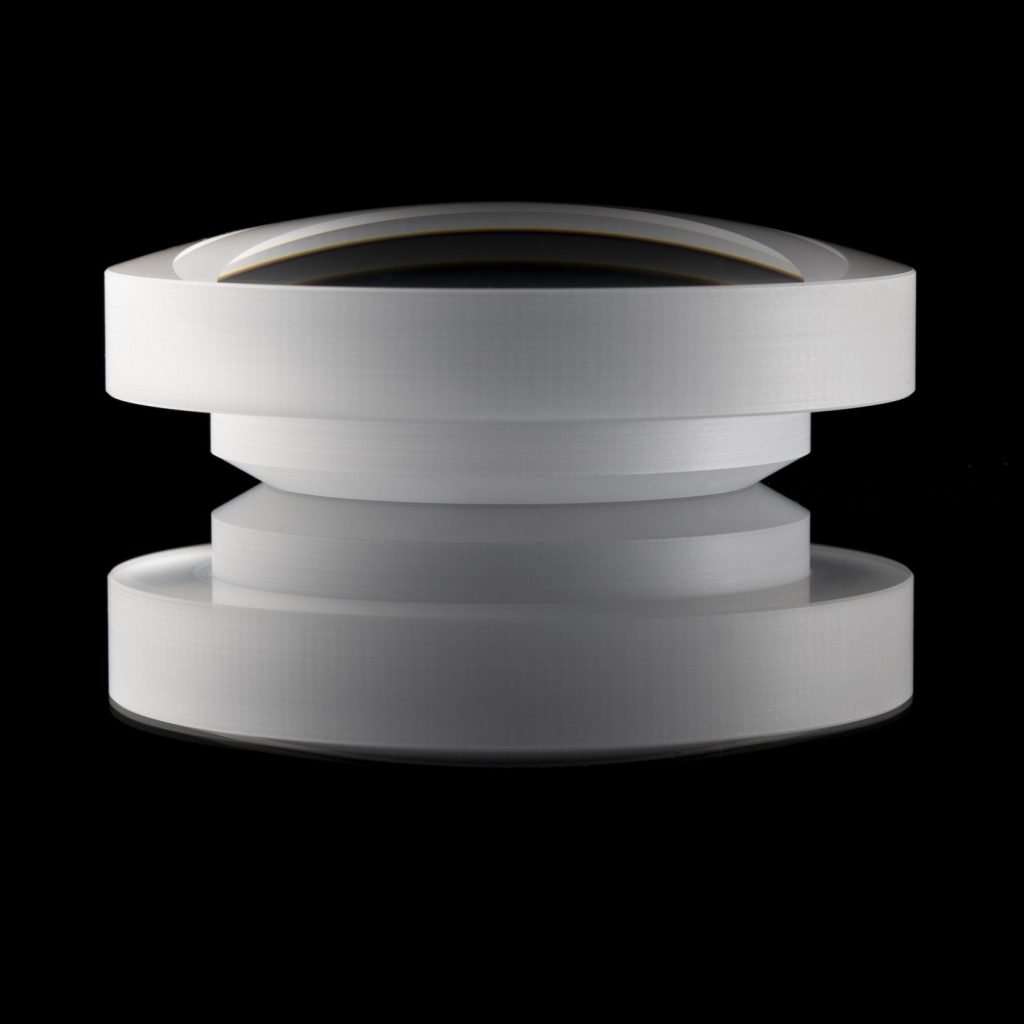

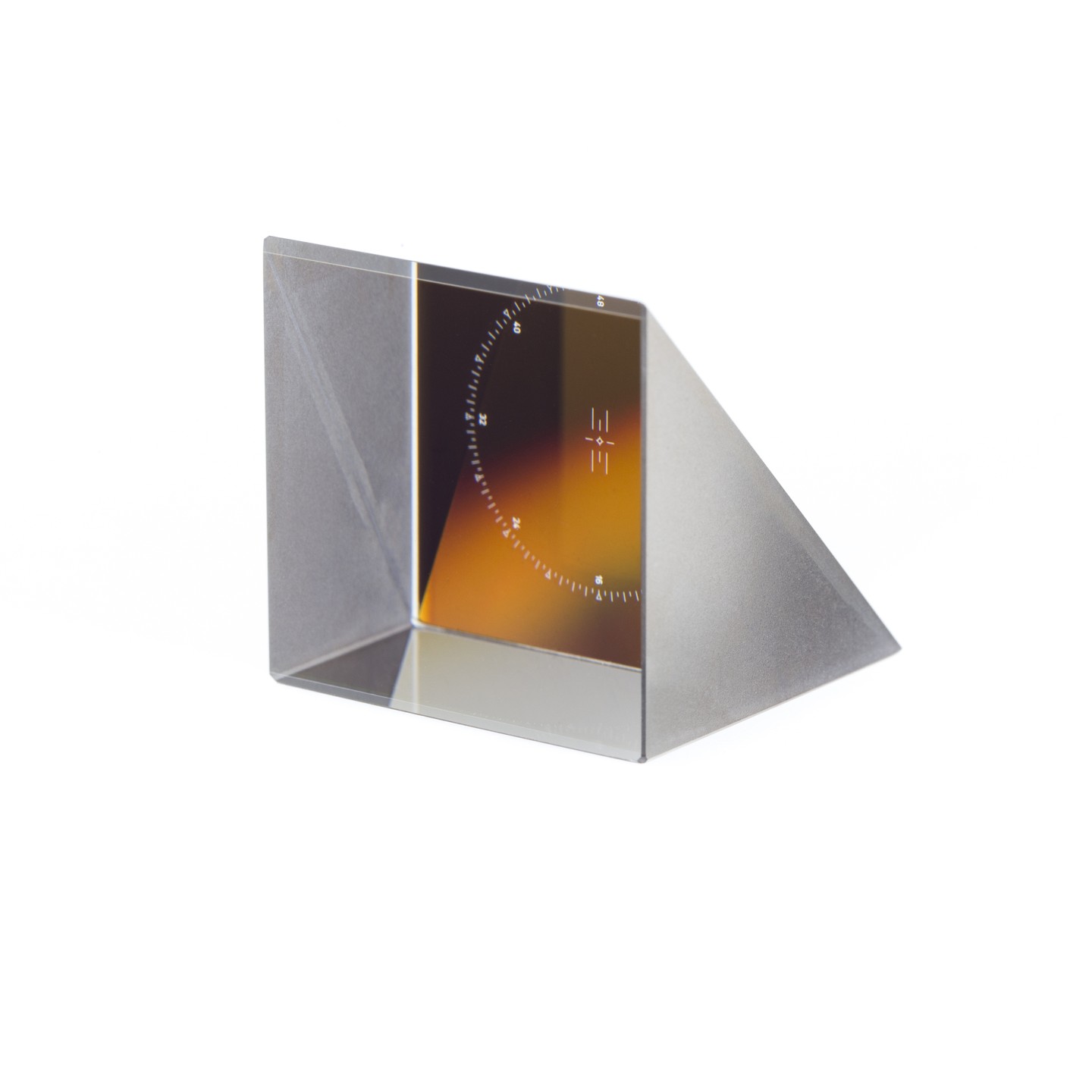

Customized solutions

Our engineers develop solutions for requirements that cannot be implemented with off-the-shelf optics. And no project is too small or great for consideration.

We offer you our many years of experience in project management, a structured development process and close cooperation to ensure your success.

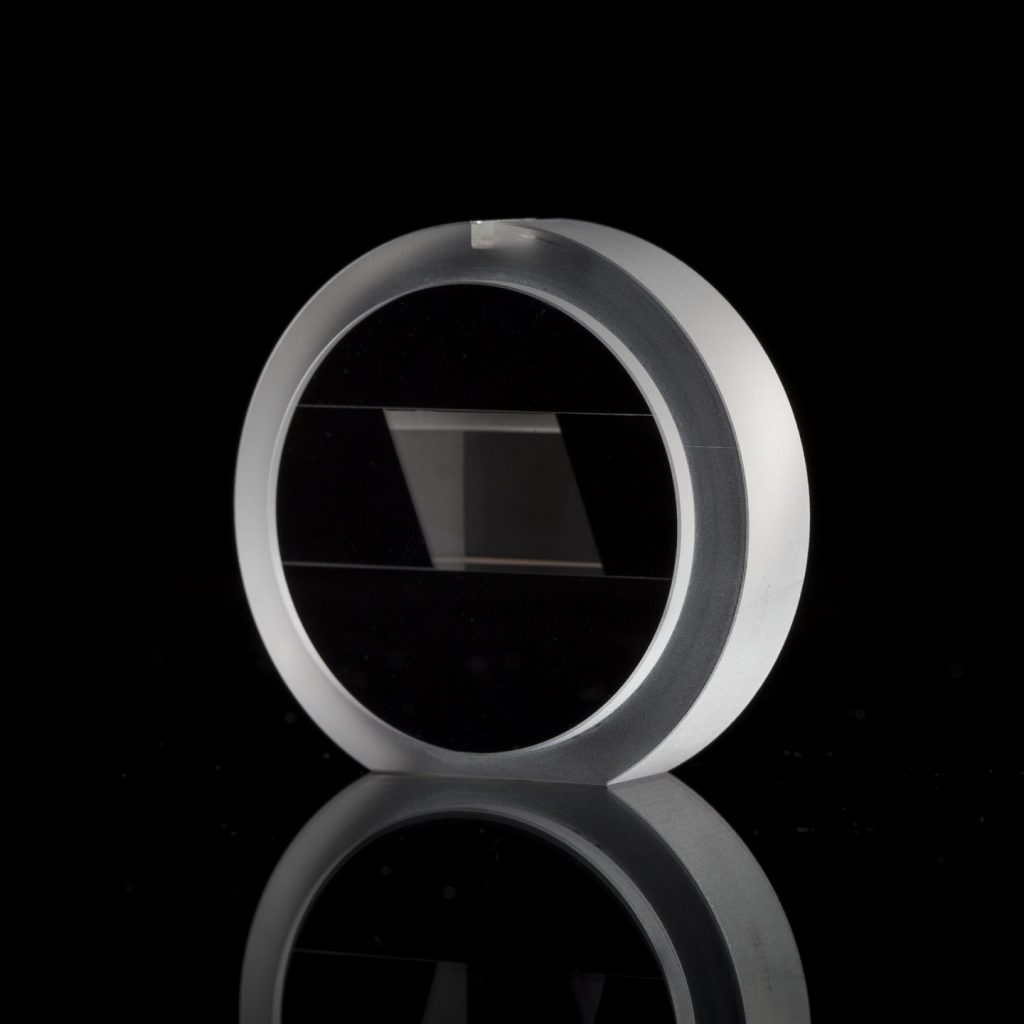

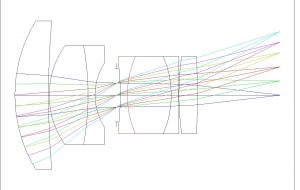

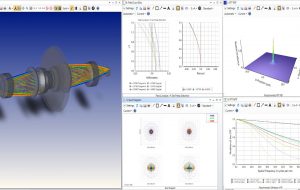

From design to series production

Whether you have only a product idea, a problem to overcome, or wish to contract for manufacturing a finished optical design − we can meet your needs at any state of project readiness to develop and manufacture your solution from concept to serial production.

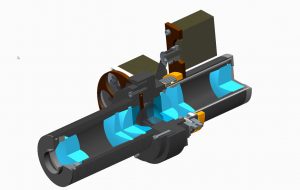

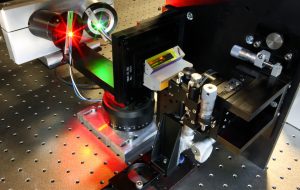

In-house manufacturing

Our in-house optics production, including coating, is the foundation for rapid implementation of developed products from concept to production. Our developers, designers and production technologists work closely together from the start to ensure we offer you manufacturable and economical solutions.

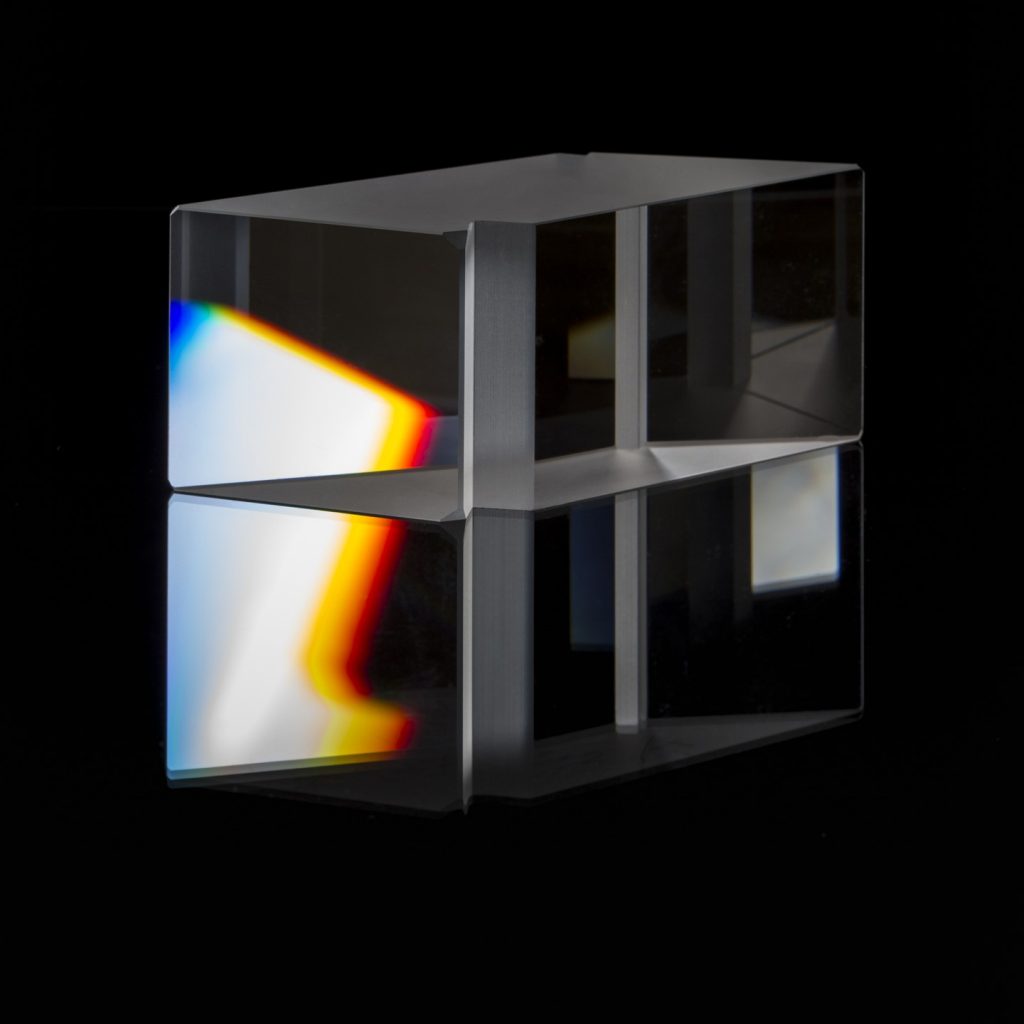

R&D support and product lifecycle management

After successful development and initiation of production, we support you throughout the entire product lifecycle. We provide support for further product developments or necessary technical changes while managing complex supply chains.